The stock intake was an advanced design when it came out in 1987. On a stock engine, the flow is sufficient to provide the engine with enough air. My guess is that the GTS was reaching the limits of the intake flow capabilities. So it stands to reason, that anything over 5.4 liters requires more air flow than the stock intake can provide.

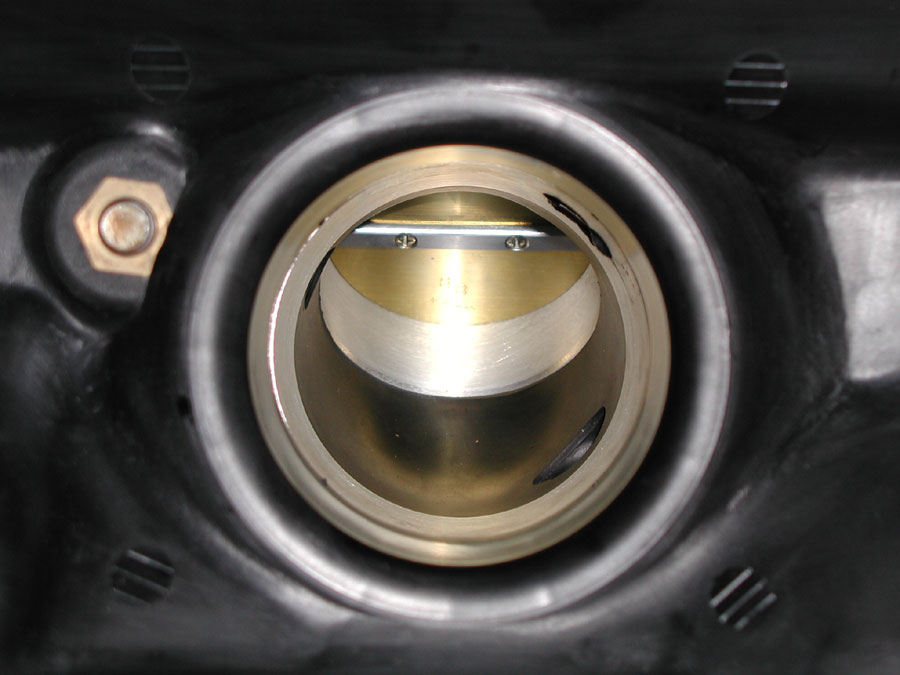

My previous improvements to the air flow into the intake started with 3 inch silicone air tubes. Louie Ott had found some small increases in horsepower by reshaping the bottom of the S4 air filter housing to mirror the 85-86 air box bottom which is deeper & had a nice smooth radius edge where the air flows into the mass air flow sensor. Since I don't have a mass air flow sensor, I borrowed an 86 air filter housing bottom to see if I could make it work. I decided to modify my old air tube to work with the 86 air box. It was a better fit with the 968 cam covers than the stock S4 air box bottom. Here is what it looks like from inside the air box...

Louie indicated that he only saw a 5-7 horsepower and 5-7 foot lbs of torque increase by reshaping an S4 airbox on a stock engine. Interestingly enough the torque increase was in the lower RPM ranges and the horsepower was on the upper end. I don't think the gain is huge, but for the cost of a used airbox bottom ($75) it was worth the time to make it fit. I wanted to have the best possible airflow into the engine, while keeping a semi stock look under the hood.

Since I am trying to get every possible performance gain, I decided to have the throttle body enlarged..... Here is the stock throttle body:

I colored a section with a black paint pen to show the the mouth of the throttle body as it ramps to a smaller diameter. The very edge is 80mm and the smaller diameter where the butterfly is 74mm, which gives us some room to work with.

I sent it to Ed @ Big Bore Throttle Bodies and he machined it out to 79mm, and added a larger butterfly:

The larger butterfly easier to notice when looking at the cross bar and the notches that were flush with the sides of the bore originally but are now exposed.

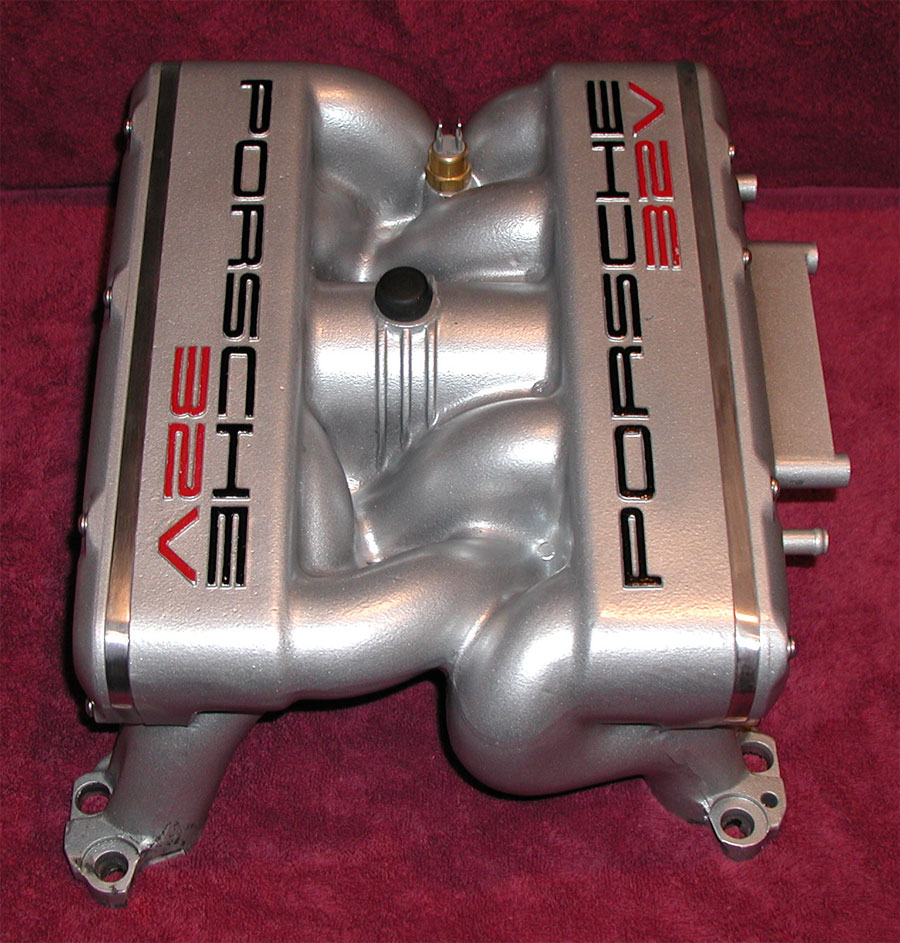

Another area where a larger displacement engine exploits the intake's weakness is the air flows from the plenums into the actual runners. The side plates on the intake are very close to the runners. Here is a side view of the intake from with the side plate removed.

I had some spacers made out of 3/8th inch aluminum to move the side plates away from the intake runner mouths. 3/8th of an inch is as much as you can space the side plates out, as the fuel rails are in the way. I wanted to keep the stock fuel rails. This modification also increases the volume of the intake plenums. I decided to polish the spacers instead of having them powder coated to match the intake and cam covers.

With the wider intake plenums, the factory fasteners would have interfered with the fuel rails so I found some really cool stainless button headed pieces that were longer and used them to replace the factory fasteners. Here is a pic of the side:

When the heads were ported the intake was port matched. Stock intake runners are 50mm wide, and mine are 55mm wide to match the head ports.

On the top is a stock intake gasket, compared to the 968 intake gasket which I use on the bottom.

Here I laid the 968 gasket over the 928 gasket to show the differences:

Well, this about covers the intake mods.......

Heads

& VarioCam